Silicone thermal tubes are an essential component in various industries, including automotive, electronics, and aerospace. These tubes are used to transfer heat from one place to another efficiently, making them crucial for maintaining the optimal performance of machinery and equipment. The production process of silicone thermal tubes involves several steps to ensure the highest quality and performance. In this article, we will explore the mainstream production process of silicone thermal tubes in detail.

The first step in the production of silicone thermal tubes is the selection of raw materials. Silicone rubber is the primary material used in the manufacturing of these tubes due to its excellent thermal conductivity, flexibility, and resistance to high temperatures. The quality of the silicone rubber plays a crucial role in determining the performance and durability of the thermal tubes. Therefore, manufacturers carefully select high-quality silicone rubber that meets the required specifications and standards.

2. Mixing and compounding

Once the raw materials are selected, the next step is mixing and compounding. In this process, the silicone rubber is mixed with various additives and fillers to enhance its properties. These additives may include heat stabilizers, flame retardants, and reinforcing agents to improve the thermal conductivity, flexibility, and durability of the silicone thermal tubes. The mixing and compounding process is carried out in specialized equipment to ensure uniform distribution of additives throughout the silicone rubber.

3. Extrusion

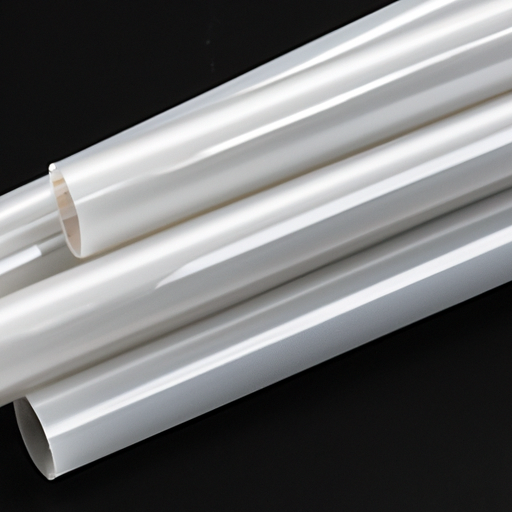

After the mixing and compounding process, the silicone rubber is fed into an extrusion machine to form the thermal tubes. Extrusion is a manufacturing process in which a material is forced through a die to create a continuous profile with a specific cross-sectional shape. In the case of silicone thermal tubes, the extrusion process shapes the silicone rubber into a tube with the desired diameter and thickness. The extruded tubes are then cooled and cured to set the shape and properties of the silicone rubber.

4. Vulcanization

Vulcanization is a critical step in the production of silicone thermal tubes as it enhances the mechanical properties and heat resistance of the silicone rubber. In this process, the extruded tubes are exposed to heat and pressure to cross-link the polymer chains in the silicone rubber. This cross-linking process improves the tensile strength, elasticity, and thermal stability of the tubes, making them suitable for high-temperature applications. Vulcanization is typically carried out in specialized ovens or autoclaves under controlled conditions to ensure uniform curing of the silicone rubber.

5. Cutting and finishing

Once the silicone thermal tubes are vulcanized, they are cut to the desired length and finished to meet the required specifications. The cut tubes are inspected for any defects or imperfections and trimmed to ensure a smooth and uniform surface. Depending on the application, the tubes may undergo additional processes such as surface treatment, printing, or packaging before they are ready for shipment to customers.

6. Quality control

Throughout the production process, quality control is essential to ensure that the silicone thermal tubes meet the required standards and specifications. Manufacturers conduct various tests and inspections to check the physical, mechanical, and thermal properties of the tubes. These tests may include measurements of diameter, thickness, hardness, and thermal conductivity, as well as visual inspections for any defects or irregularities. Quality control measures help to identify any issues early in the production process and ensure that only high-quality silicone thermal tubes are delivered to customers.

In conclusion, the production process of silicone thermal tubes involves several steps to ensure the highest quality and performance. From raw material selection to extrusion, vulcanization, and finishing, each stage plays a crucial role in shaping the properties and characteristics of the tubes. By following a systematic and controlled manufacturing process, manufacturers can produce silicone thermal tubes that meet the stringent requirements of various industries and applications. With their excellent thermal conductivity, flexibility, and durability, silicone thermal tubes continue to be a vital component in the efficient transfer of heat in modern machinery and equipment.